It is used to fill in the gap between the big plansifter and the laboratory plansifter. Therefore, it provides great advantages.

The capacity of the plansifter is determined by taking into consideration the kind of application and the grade of silk cloth.

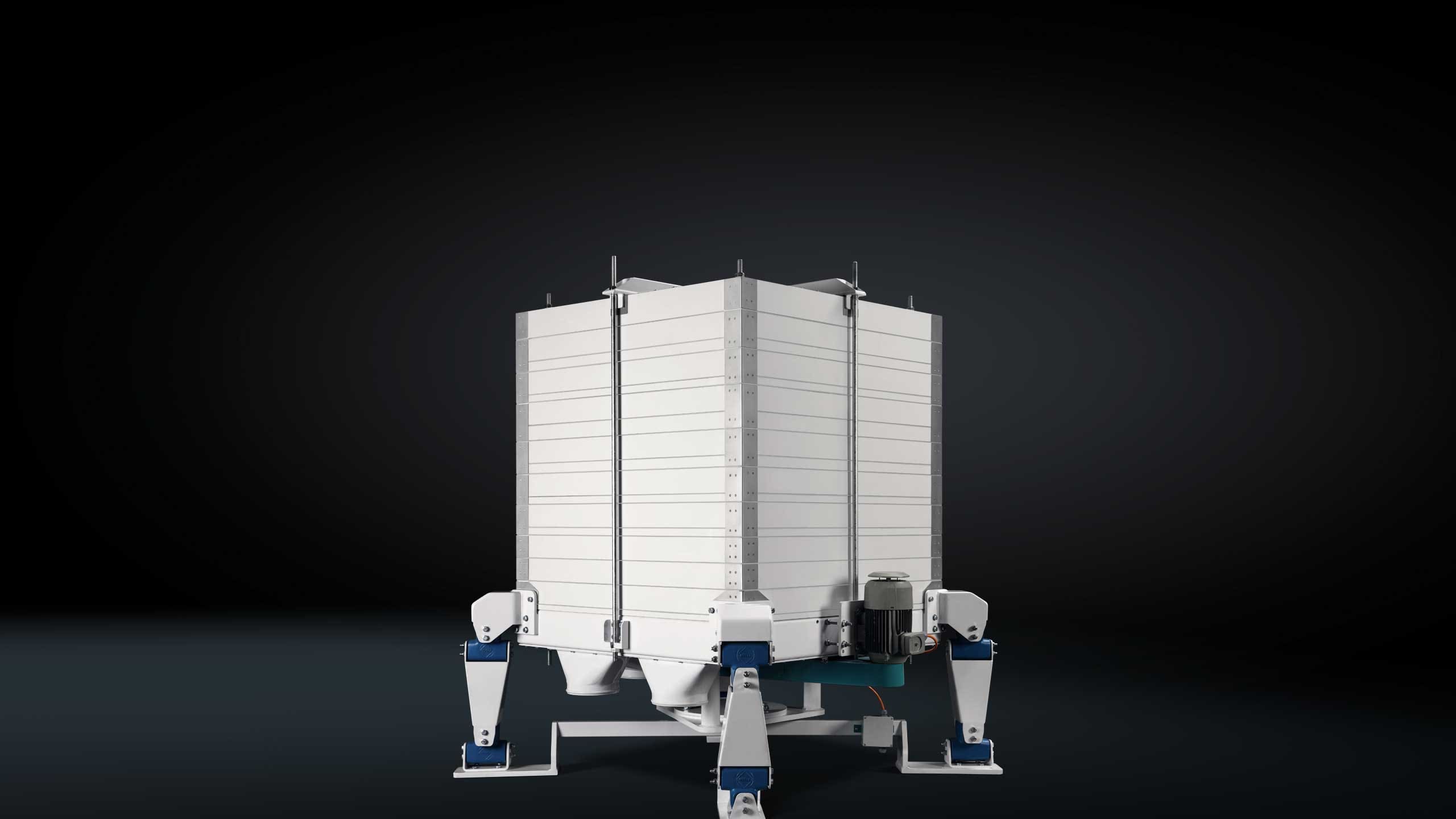

Vibrating process is maintained by means of vibro-motors, which are placed in the center of gravity of the machine. The grain feeding chamber and body which are mounted on the rubber shock absorbers by vibrating together and driven by vibro-motors convey the product into midsection of inlet. The grain is separated uniformly on the entire surface of the screen by means of an adjustable regulating gate.