According to World Health Organization, WHO and Centers for Disease Control and Prevention, CDC; Iron deficiency anemia is the most widespread nutritional deficiency in the world and has importance consequences for child development and enormous economic costs. Likewise, according to WHO, CDC and International Clearinghouse for Birth Defects Surveillance and Research, ICBDSR; Neural tube defects are among the most common structural congenital anomalies worldwide, with an estimated 300,000 cases per year and contribute to 10% of deaths during the first 28 days of life. Obviously, the best way of preventing micronutrient malnutrition is to ensure consumption of a balanced diet that is adequate in every nutrient. Unfortunately, this is far from being achievable everywhere since it requires universal access to adequate food and appropriate dietary habits. From this standpoint, food fortification has the dual advantage of being able to deliver nutrients to large segments of the population without requiring radical changes in food consumption patterns.

According to World Health Organization, WHO and Centers for Disease Control and Prevention, CDC; Iron deficiency anemia is the most widespread nutritional deficiency in the world and has importance consequences for child development and enormous economic costs. Likewise, according to WHO, CDC and International Clearinghouse for Birth Defects Surveillance and Research, ICBDSR; Neural tube defects are among the most common structural congenital anomalies worldwide, with an estimated 300,000 cases per year and contribute to 10% of deaths during the first 28 days of life. Obviously, the best way of preventing micronutrient malnutrition is to ensure consumption of a balanced diet that is adequate in every nutrient. Unfortunately, this is far from being achievable everywhere since it requires universal access to adequate food and appropriate dietary habits. From this standpoint, food fortification has the dual advantage of being able to deliver nutrients to large segments of the population without requiring radical changes in food consumption patterns.

There always has been a confusion between enrichment and fortification terms and most of the times, they are used interchangeably. Pyler and Gorton describes “enrichment” as the practice of adding back vitamins and minerals lost during processing while “fortification” as supplementation with nutrients not previously present in the food or not naturally occurring at such high levels. They also indicated that enrichment describes the addition of the B vitamins and iron to flour because losses in these materials range from 60 to 80% in flours with an extraction rate of 70 to 75%. WHO/FAO defines food fortification as “the addition of one or more essential nutrients to a food, whether or not it is normally contained in the food, for the purpose of preventing or correcting a demonstrated deficiency of one or more nutrients in the general population or specific population groups “. This process usually takes place during the processing of staple foods at a central level so that it reaches a considerable proportion of the at-risk populations without requiring their active participation.

Food fortification is one of the leading public health interventions recommended to prevent and control micronutrient deficiencies. Staple foods and condiments are among the foods most commonly fortified with vitamins and minerals. Wheat flour was the first cereal grain product to be widely fortified, and the first cereal grain recommendations issued by the WHO pertained to maize and wheat flour.

Fortification of industrially processed flour, when appropriately implemented, is an effcient, simple and inexpensive strategy for supplying vitamins and minerals to the diets of large segments of the population. Adding iron to flour during the milling process helps reduce the risk of iron-deficiency anemia since it is caused by iron deficiency and wheat flour is the staple most commonly fortified with iron in large-scale fortification programs. The mandatory fortification of wheat flour with Fe significantly furthered the reduction in the prevalence of inadequate intake, except among women of reproductive age, and changed the main contributors to this nutrient in the studied population. Therefore, monitoring of Fe addition in flour is essential to assess compliance to the fortified flour policy and to guarantee a safe Fe intake for all the population.

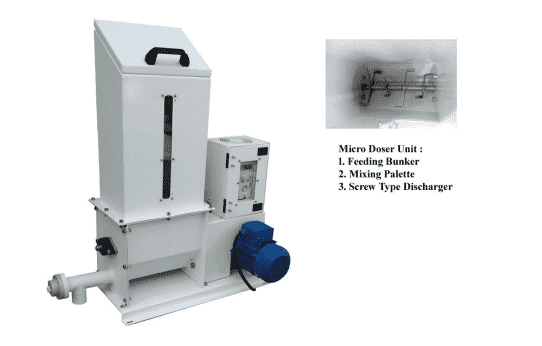

Fortification of industrially processed flour, when appropriately implemented, is an effcient, simple and inexpensive strategy for supplying vitamins and minerals to the diets of large segments of the population. Adding iron to flour during the milling process helps reduce the risk of iron-deficiency anemia since it is caused by iron deficiency and wheat flour is the staple most commonly fortified with iron in large-scale fortification programs. The mandatory fortification of wheat flour with Fe significantly furthered the reduction in the prevalence of inadequate intake, except among women of reproductive age, and changed the main contributors to this nutrient in the studied population. Therefore, monitoring of Fe addition in flour is essential to assess compliance to the fortified flour policy and to guarantee a safe Fe intake for all the population. During fortification process in the mill, use of micro dosing and proper mixing mechanism are important for correct amount and uniform distribution of fortification agents in flour. The most common way to fortify flour is to use the equipment called feeder or in practice as micro doser machine, which is used at flour blending stage just before packaging operation. This adds premix to flour precisely at pre-determined rates in the process of flour production. The micro doser device is easily reachable that it is supplied by Alapala, Henry Simon and other leading milling equipment manufacturers. Three types of feeders are available: screw, revolving disk and drum or roller. Mills generally need one feeder per for each type of flour or meal line to be fortified, and the size and number of feeders needed depends on the amount of flour produced per hour. The operating principle of micro doser unit is basically pre-mixing of product and ingredients with a steel palette mixer, then adding into flour sensitively in gram levels with a discharge mechanism. The unit is also an electronically controlled for a sensitive adjustment of feeding speed and amount etc. according to the process.

During fortification process in the mill, use of micro dosing and proper mixing mechanism are important for correct amount and uniform distribution of fortification agents in flour. The most common way to fortify flour is to use the equipment called feeder or in practice as micro doser machine, which is used at flour blending stage just before packaging operation. This adds premix to flour precisely at pre-determined rates in the process of flour production. The micro doser device is easily reachable that it is supplied by Alapala, Henry Simon and other leading milling equipment manufacturers. Three types of feeders are available: screw, revolving disk and drum or roller. Mills generally need one feeder per for each type of flour or meal line to be fortified, and the size and number of feeders needed depends on the amount of flour produced per hour. The operating principle of micro doser unit is basically pre-mixing of product and ingredients with a steel palette mixer, then adding into flour sensitively in gram levels with a discharge mechanism. The unit is also an electronically controlled for a sensitive adjustment of feeding speed and amount etc. according to the process.

In Africa, 26 countries have mandates to fortify wheat flour. Nine of these countries also require fortification of maize flour. Six countries in this region fortify more than half of their industrially milled wheat flour even though it is not mandatory. In early 2011, FFI conducted an exhaustive analysis of flour fortification opportunities in Africa and found that seven countries were fortifying at least 75% of their industrially milled wheat flour. FFI believes that currently 19 countries are fortifying at least 75% of their industrially milled wheat flour with at least iron and folic acid at levels that are expected to make a health impact. In Africa, South Africa and Nigeria were the first two countries to fortify flour.

Wheat flour fortification is a preventive food-based approach to improve micronutrient status of populations over time that can be integrated with other interventions in the efforts to reduce vitamin and mineral deficiencies when identified as public health problems. Wheat flour fortification programs could be expected to be most effective in achieving a public health impact if mandated at the national level and can help achieve international public health goals.

Decisions about which nutrients to add and the appropriate amounts to add to fortify flour should be based on a series of factors including the nutritional needs and deficiencies of the population; the usual consumption profile of “fortifiable” flour (i.e. the total estimated amount of flour milled by industrial roller mills, produced domestically or imported, which could in prin¬ciple be fortified); sensory and physical effect of micro ingredients on flour and flour products; fortification of other food varieties; population consumption of vitamin and mineral supplements; and costs.

Flour fortification programs should include appropriate Quality Assurance and Quality Control (QA/QC) programs at mills as well as regulatory and public health monitoring of the nutrient content of fortified foods and assessment of the nutritional/health impacts of the fortification strategies. In addition, those requirements, to have a sustainable and successful flour fortification program, local culture and multi-sector national fortification alliance are also utmost importance.

In conclusion, as flour millers we have a responsibility of to feed billions of people throughout the world, not only satiate them but also make healthier. Fortified foods have health and nutrition value added so it will increase the competitiveness of the industry.