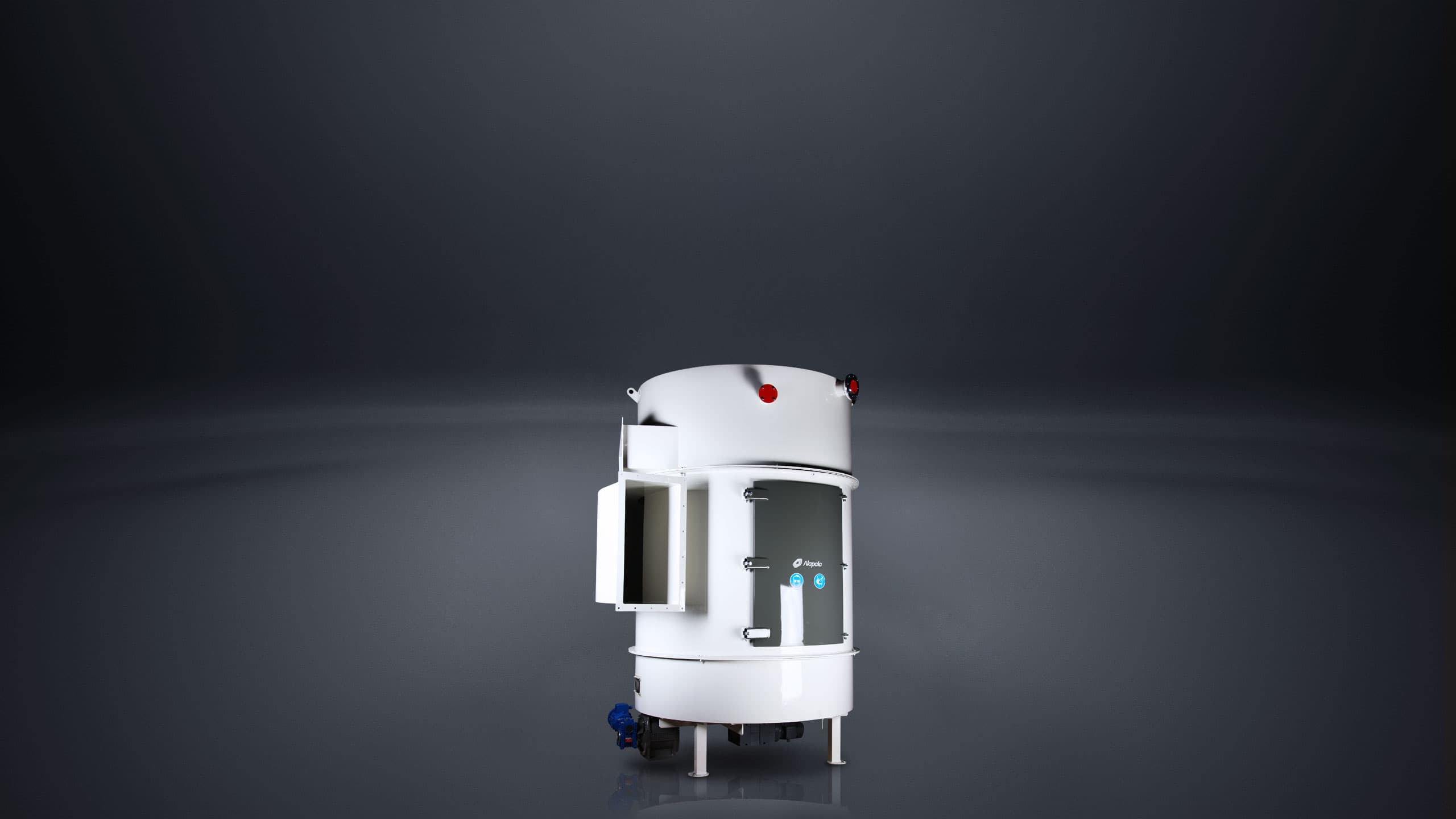

Suitable to separate dust and other particles suspended in air of cleaning department aspirator system before being discharged to the outside with a bottom scraper.

N1 Filtration phases in the N1 bag: The dusty air is purified (filtrated) in the outer surface of the hose type filter bag. N2 Final cleaning phase in the N2 bag: Dust loaded outer surface of the filter bags is cleaned respectively by blowing air from inside of bags. The accumulated dust is discharged out of the air lock due a scraper.